A two-point single-drive lifting system is a mechanical device used to lift and move loads. The basic components in this system include two screw jacks, a reversing mechanism, and a motor.

The advantage of this system is that a single motor can be used to drive both points, allowing loads to be lifted evenly and balanced. The reversing mechanism driven by the motor ensures that loads are moved symmetrically, which is especially important for precise and balanced lifting operations.

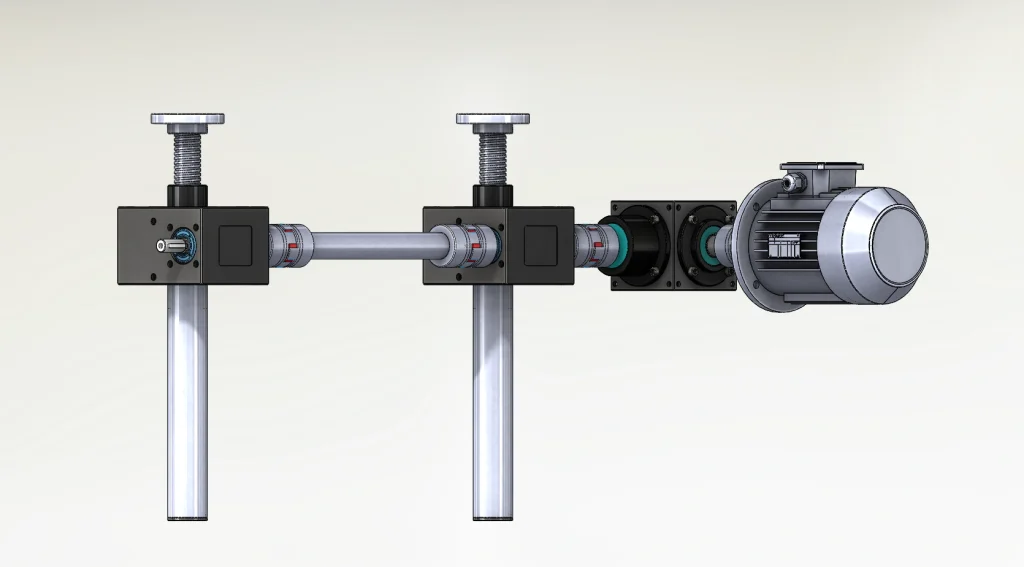

A two-point single-drive lifting system is a mechanical device used to lift and move loads. The basic components in this system include two screw jacks, a reversing mechanism, and a motor.

The advantage of this system is that a single motor can be used to drive both points, allowing loads to be lifted evenly and balanced. The reversing mechanism driven by the motor ensures that loads are moved symmetrically, which is especially important for precise and balanced lifting operations.

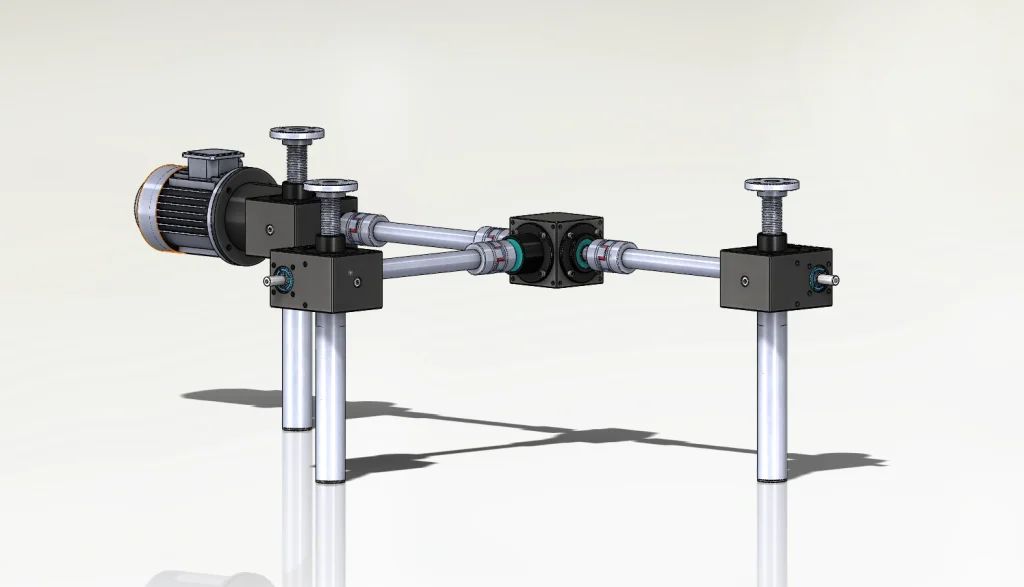

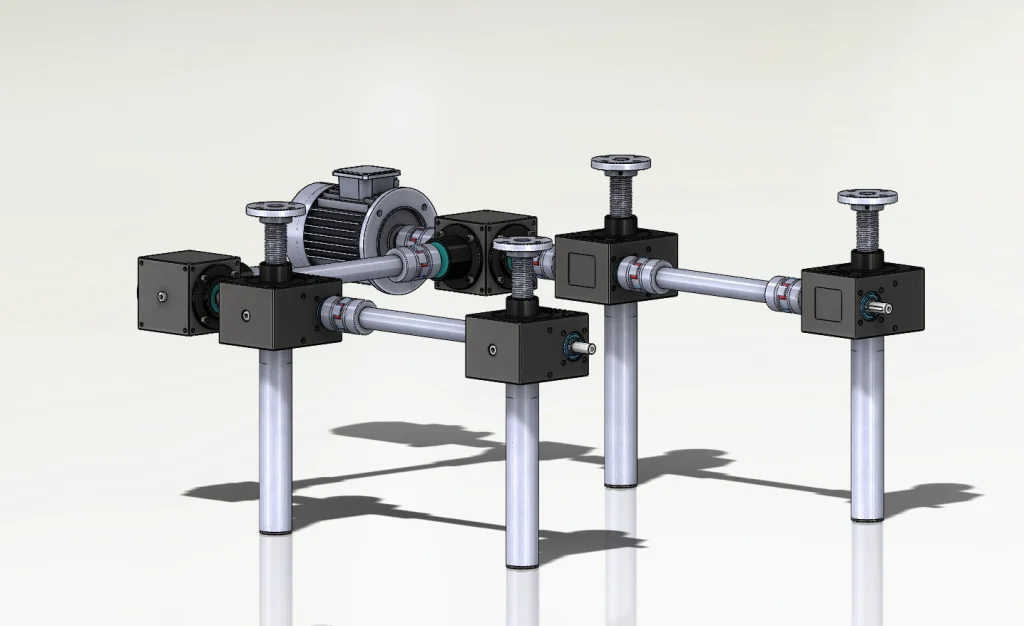

The system consists of an electric motor, a direction changer and three screw jacks. The electric motor transmits its rotary motion to the direction changer via the shaft and couplings. The direction changer transfers this motion to the right and left at a 90° angle, providing power distribution in both directions. The screw jacks at both ends and the screw jack in the middle work synchronously, so that the platform or structure supported by the system is lifted or lowered simultaneously and balanced from three different points. This structure is suitable for high precision and stable lifting operations and is widely used in industrial applications. Thanks to the bearing housings and coupling connections, vibration is reduced to a minimum, ensuring efficient and safe operation.

The system consists of an electric motor, two reversing valves and four screw jacks. The rotary motion produced by the motor via the shaft and couplings is transmitted to the centre via the first reversing valve and from there to the screw jacks positioned opposite the second reversing valve. The four screw jacks are positioned at the corners of the platform and work synchronously, ensuring balanced and simultaneous lifting of the load. This structure prevents deviation in the horizontal plane and allows safe lifting of especially large or unbalanced loads. The system offers high stability and safety in industrial machines, heavy-duty platforms and applications requiring precise positioning.

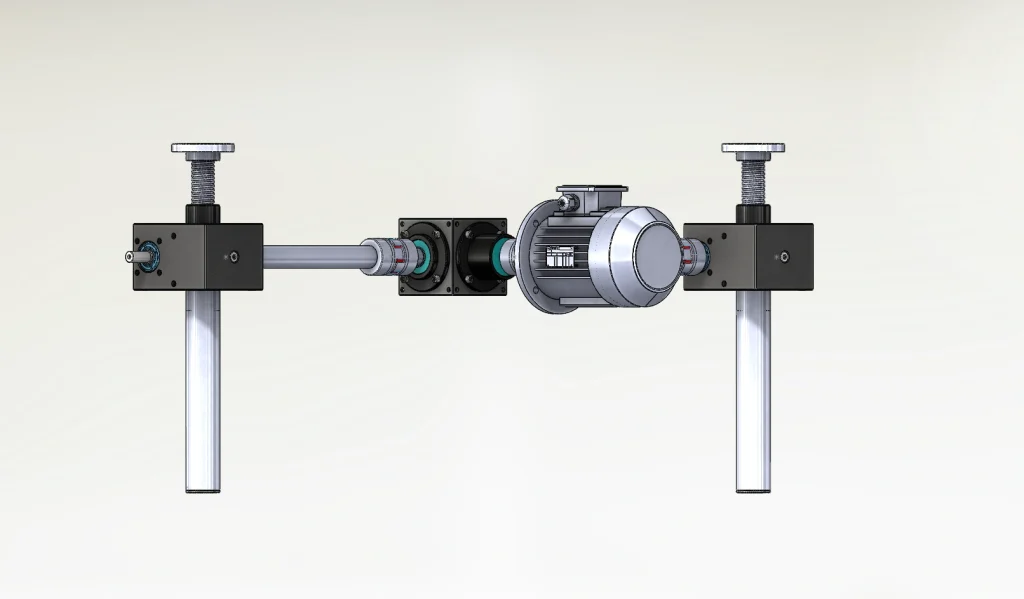

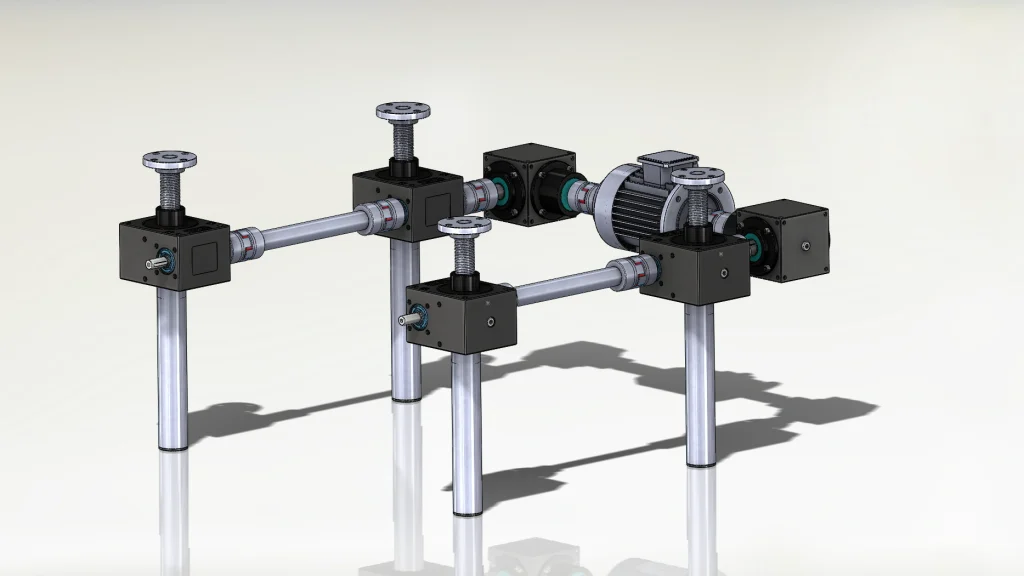

It consists of a double shaft output electric motor, two direction changers and four screw jacks. The rotary motion from both ends of the motor is transmitted to the right and left direction changers via shafts and couplings. These direction changers transfer the torque to the screw jacks placed opposite each other by turning them at a 90° angle. The four screw jacks are positioned at the four corners of the system and operate synchronously, ensuring that the platform is lifted smoothly, balanced and simultaneously. The use of a double shaft output motor enables symmetrical distribution of the load and more efficient power transmission. This structure is ideal for industrial lifting applications that require positioning accuracy and stability.

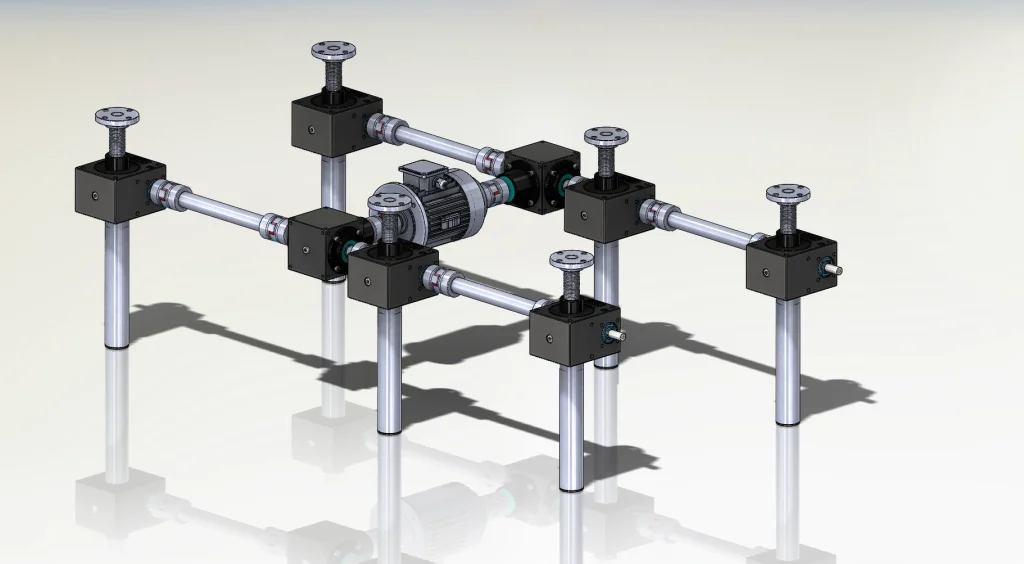

It consists of a double shaft output electric motor, two direction changers and six screw jacks. The rotary motion from both ends of the motor is transmitted to the direction changers via shafts and couplings. These direction changers distribute the torque to the screw jacks to which they are connected by turning them at a 90° angle. The six screw jacks are symmetrically placed at six points of the system and operate synchronously, ensuring smooth, balanced and simultaneous lifting of large or long platforms. This structure offers both high positioning accuracy and structural stability in multi-point load carrying applications. The system is especially preferred in industrial areas where controlled lifting of large surface loads or unbalanced masses is required.